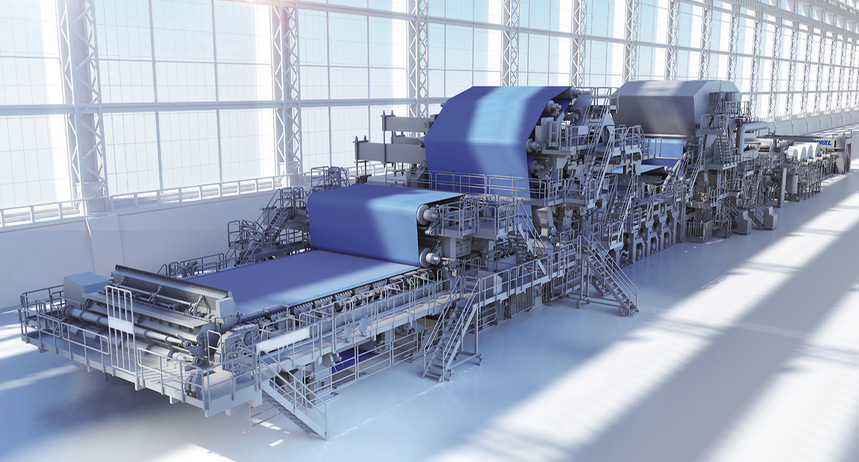

HENGDA capabilities for recycled fiber production.

We deliver complete production lines or individual components for the recycling of packaging grades or fibers containing ink deposits for the wastepaper processing and recycled fiber production.

The challenge

While recycling paper products is a wonderful way for consumers to assist in the re-use of natural resources, the processing of recycled fibers puts new demands on papermakers. Some of the key challenges are how to handle the varying quality of incoming materials, how to remove contaminants (glues, metals, inks, etc.) before the papermaking process, and how to increase the yield of recycled fiber production to make it economically beneficial.

The solution

HENGDA provides technologies for recycled fiber processing and stock preparation, including sludge and water handling applications. These technologies are proven in reference installations around the world. They have one common purpose – process and deliver high quality fiber with the highest yield and the lowest energy consumption. Our technology portfolio for recycled fiber producers comprises world-class equipment for all major categories of wastepaper: deinked, old containers, old magazines or newspapers, office waste, etc. All main processes are covered: from initial wastepaper handling to pulping, cleaning, bleaching, and preparing the stock for the paper machine. Every component is designed to work independently in a rebuild or modernization application, or perfectly integrates with other HENGDA machinery in a complete line for new installations. Experienced HENGDA project teams give you support during engineering, planning, erection, and start-up of your mill. Technical and service support is at-the-ready throughout the life of the equipment.